While using packaging tape or applying it to an item, have you ever wondered how it knows when to stick or when to let go? Or why some packaging tapes stay secure in rough shipping conditions and others fail miserably?

The answer is the adhesive technology behind the tape. At Bagla Group, this technology is at the heart of every packaging solution. So, to keep you updated, this blog will introduce you to the science behind how packaging tape adhesive works. Here, you will explore different adhesive types and explain what makes Bagla Group’s tapes reliable, durable, and industry-preferred.

What Is Adhesive in Packaging Tape?

In simple words, adhesive is a sticky substance on one side of the tape. This substance enables it to bond to surfaces. Most of the packaging tapes, especially from Bagla Group, use pressure-sensitive adhesives (PSAs). These adhesives are very helpful to form a bond when pressure is applied, without any activation by heat or water.

The adhesive layers they use are very thin but powerful. It is designed to flow into microscopic pores on the surface and hold firm through a combination of physical and chemical forces.

How Packaging Tape Adhesive Works? – Science of Adhesion

Here you will get to know about the 3 key mechanisms involved in how a packaging tape adhesive functions:

1. Adhesion

Adhesion is the ability of tape to bond to the surface, like cardboard, metal, or plastic. When the pressure is applied, the adhesive flows into the surface irregularities and grabs hold.

2. Cohesion

Cohesion is the internal strength of the adhesive material. It ensures that while using the tape adhesive doesn’t split or tear. If you find the cohesion value high, then it indicates that the tape won’t leave sticky residues or fall apart.

3. Tack

When the tape first touches the surface and it shows an initial stickiness, it is known as tape. A high-tack adhesive bonds instantly, while a low-tack adhesive allows repositioning before firming up.

Types of Tape Adhesives Through Which Packaging Tape Adhesive Works

To work as per the needs of the consumers, the packaging tape industry, like Bagla Group, uses various types of tape adhesives. Because each type of adhesive has its own properties and works for specific requirements. So the engineered adhesives in different packaging tapes, depending on application needs, are:

- Acrylic Adhesives (Used in BOPP Tapes)

These adhesives are used in the BOPP tapes products because they provide long long-lasting bond. By using these adhesives, a tape manufacturer can engineer UV and weather-resistant tapes. Acrylic adhesives are a suitable choice for both hot and cold temperatures. The tapes manufactured using acrylic adhesives are ideal for long-term storage, shipping, and export packaging.

- Rubber-Based Adhesives (Used in Double-Sided Tapes)

These adhesive choices are one of the reliable solutions for double-sided tapes. Using these adhesive tapes can simply provide excellent initial tack. These adhesives can adhere to low-energy surfaces like plastics. A better option for short-term applications. The tapes are manufactured with rubber-based adhesives commonly used in the general-purpose packaging and office supplies.

- Hot Melt Adhesives (Used in Reinforced or Filament Tapes)

These adhesives are used in the production of reinforced or filament tapes. A reliable choice to provide high tack and a strong bond & great shear resistance. These adhesive tapes are generally excellent for heavy-duty bundling and sealing.

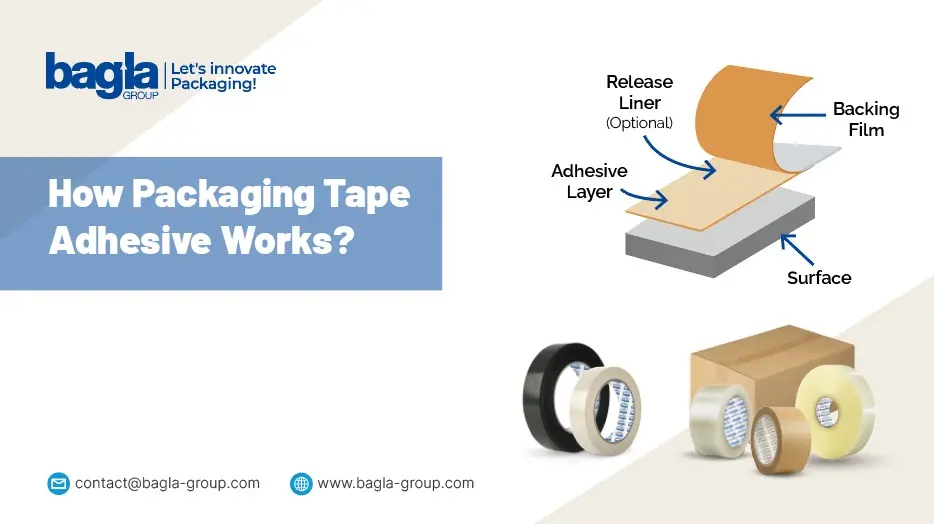

Structure Of Adhesive Tapes

The structure of the adhesive tapes consists of the following:

- Release Liner (Optional) – Used in double-sided tapes to protect the adhesive.

- Adhesive Layer – Pressure-sensitive material that activates on contact.

- Backing Film – Material like BOPP, Kraft, or reinforced fibers providing strength.

- Printing Layer (Optional) – Used for branding or tamper-evident security.

This one is the safest structure for the adhesive tapes. This multiplayer structure is used by the Bagla Group, and it ensures that the tapes of not just sticky, but also reliable and secure.

How Tape Manufacturers Ensure Long-Lasting Adhesion?

If you are willing to understand how the tape manufacturers ensure long-lasting adhesion and how packaging tape adhesive works, then you must understand the below:

Formulation Testing

Each adhesive bunch goes for the lab testing to ensure consistent tack, peel strength, and cohesion across temperature and humidity conditions.

Temperature Tolerance

The manufacturing firms of tapes (Bagla Group) retain performance in both low and high temperatures, making them ideal for cold storage, export shipping, and warehouse usage.

Moisture and UV Resistance

Selected adhesives are formulated to resist humidity and sunlight exposure. It is very crucial for long-distance or long-term storage.

Eco-Friendly Options

Most of the well-reputed companies, such as Bagla Group, offer kraft paper tapes with natural rubber-based adhesives for customers prioritizing sustainable packaging.

Conclusion – Packaging Tape Adhesive Works

As per the above-mentioned information, you can justify how the packaging tape adhesive works. The packaging tapes have multiple features and structures that ensure that the tapes are manufactured by the packaging tape manufacturers to work as per your requirements. Here we have mentioned the best packaging tape manufacturer that works as per your requirement and can also. So, before diving into the industry must ensure to choose the best packaging tapes provider.

What Is The Best Adhesive For Packaging Tape?

Each adhesives have its own property. Acrylic adhesives offer the best all-around performance for carton sealing. Hot melt adhesives are great for strength, and rubber adhesives provide high tack.

Why Do Bagla Tapes Last Longer Than Cheaper Alternatives?

Bagla uses lab-tested adhesive formulas that maintain bond strength over time, resist peeling, and handle temperature fluctuations.

Can Bagla Adhesives Handle Refrigerated Or Frozen Environments?

Yes, Bagla Group packaging tapes can simply maintain tack even in cold storage and low-temperature transit conditions.